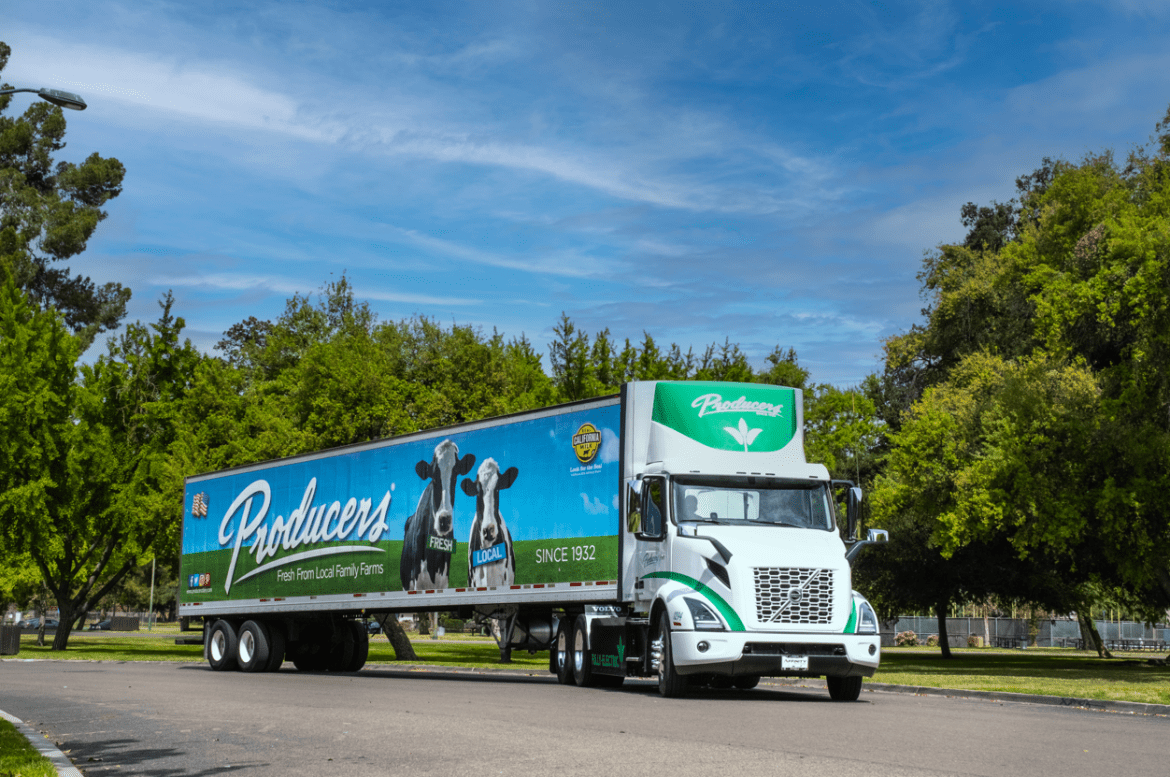

Producers Dairy, a dairy processor and direct-to-store supplier, will now deliver quality, farm-to-table freshness with zero tailpipe emissions through the integration of two Volvo VNR Electric trucks into their fleet. The Volvo VNR Electric trucks are the first commercial, battery-electric Class 8 trucks to be deployed in California’s Central Valley and were showcased at an event today at Producers Dairy’s corporate headquarters in Fresno, California.

The Volvo VNR Electric model was designed as a sustainable transportation solution for local and regional distribution, pickup and delivery, and food and beverage distribution. The two Volvo VNR Electric units will be the first Class 8 battery-electric vehicles in the company’s fleet of more than 300 trucks and will service regional distribution routes from its Fresno-based manufacturing facility to grocery stores in communities along the 40-mile stretch of Highway 99 from Selma to Madera, California.

“Through the deployment of its first two Volvo VNR Electrics, Producers Dairy is truly leading by example on the path to a more environmentally friendly future, which is at the core of the company’s mission,” said Peter Voorhoeve, president, of Volvo Trucks North America. “Our team is grateful for the investment that our dealer partner, Affinity Truck Center, made in becoming the Central Valley’s first Volvo Trucks Certified Electric Vehicle Dealer to provide Producers Dairy and other customers in the region with premium support to maximize the uptime of their Volvo VNR Electric trucks.”

Producers Dairy is a third-generation family business run by the Shehadey family. With a focus on nourishing lives, they prioritize the health of their community from the care of their cows to the sustainable delivery of their naturally produced dairy products.

“We are excited to integrate these first two Volvo VNR Electric trucks into our fleet as we work to reduce emissions on our local delivery routes,” said Scott Shehadey, president, of Producers Dairy. “This investment in zero-tailpipe-emission technology aligns with our corporate mission to enhance the quality of people’s lives, and we are grateful to each of the organizations that supported us with today’s successful vehicle deployment, including Volvo Trucks, Affinity Truck Center, the California Air Resources Board (CARB), and AMPLY Power.”

The project was supported by funding from CARB’s GGRF Zero Emission Drayage Truck Project as part of California Climate Investments. Producers Dairy received $1.25 million to purchase, install, and integrate two Volvo VNR Electric trucks into its larger fleet.

“The deployment of two zero-emission battery-electric trucks at Producers Dairy’s Fresno-based manufacturing facility shows how companies can make innovative, real-world steps to improving air quality in the Central Valley region,” said Tania Pacheco-Werner, CARB member representing the San Joaquin Valley Air Pollution Control District (SJVAPCD). “I applaud the project partners for their collaboration on getting these fully electric trucks on the road and look forward to seeing Producers Dairy utilize the lessons learned from this deployment to scale up its battery-electric fleet and charging infrastructure in the future.”

Producers Dairy worked with AMPLY Power to design and install the supporting charging infrastructure for its Volvo VNR Electric trucks and utilizes AMPLY’s Omega digital solution to monitor charging infrastructure, optimize energy costs, and maximize charger and vehicle uptime. The Fresno dairy processing facility includes two 150 kW DC fast chargers and the ability to scale for increased capacity in the future. AMPLY Power will work with Producers Dairy to maximize charging efficiency and cost-effectiveness with intelligent charge management services while ensuring that the trucks are available to complete their mission-critical deliveries.

Affinity Truck Center’s Fresno dealership will support Producers Dairy with seamless integration of VNR Electric trucks into its fleet through the Volvo Gold Contract, which incorporates maintenance, full coverage on components, and towing and uptime services. Its service team completed the robust training required as part of the Volvo Certified EV Dealer program and is prepared to safely and efficiently perform battery-electric truck maintenance and repairs.

“Deploying battery-electric fleet trucks can be a complex process that requires a customer to engage numerous stakeholders and begin planning 12 to 18 months in advance for charging infrastructure needs,” said Kim Mesfin, president, of Affinity Truck Center. “As a Volvo Trucks Certified EV Dealer, we are ready to support fleets throughout the Central Valley with their electromobility goals—including identifying ideal routes and vehicle configurations, support with incentive funding, identifying infrastructure partners, and maximizing vehicle uptime through the Volvo Gold Contract.”

Affinity’s sales team can consult with Central Valley fleets considering investing in battery-electric trucks in selecting ideal vehicle configurations by providing access to Volvo’s Electric Performance Generator (EPG) tool, which enables fleet managers to simulate real-world routes for their VNR Electric trucks, taking into consideration the vehicle configuration and battery capacity, environmental factors such as terrain and ambient temperature, and specific route details, including traffic patterns.

To learn more about Volvo Trucks North America and Volvo VNR Electric, visit the company website.